Our plants

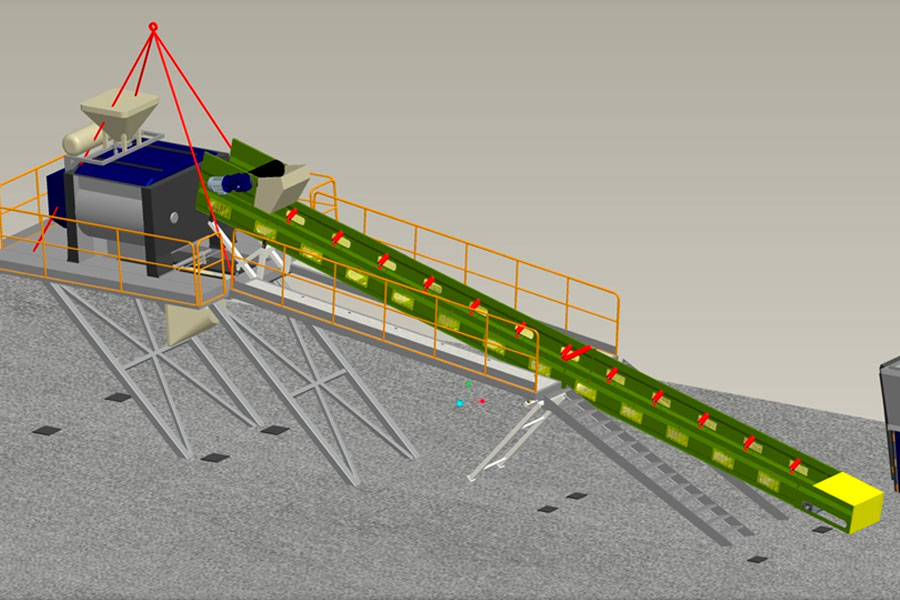

Our modular concrete batching plants are concrete batching plants consisting of pre-assembled components that can be assembled on site.

Modular concrete batching plants are used in a wide range of construction projects:

- 9Residential and commercial buildings.

- 9Infrastructure, such as roads, bridges and airports.

- 9Precast concrete works, such as walls and structures.

Components of a modular concrete batching plant

- 9Loading system: This system loads the aggregate into the batching and weighing hoppers.

- 9Silos and storage hoppers: These hoppers store the concrete components, such as cement, aggregates and water.

- 9Batching and Weighing System: These systems batch and weigh the concrete components to ensure that they are mixed in the correct proportions.

- 9Mixer: This machine mixes the concrete components until a uniform mass is formed.

- 9Discharge systems: This system discharges the concrete from the mixer into trucks or containers.

modular plants?

Classification

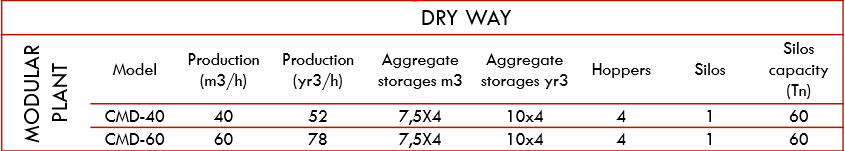

Modular concrete batching plants can be classified according to their mixing method. Dry-mix plants mix the dry concrete components before adding the water. Wet mixing plants mix all the components at the same time.

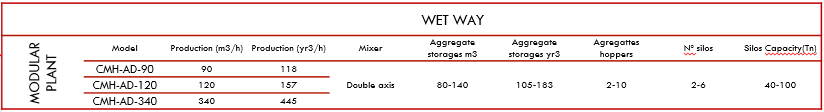

Modular concrete batching plants can also be classified according to their production capacity. Small capacity plants produce up to 20 cubic meters (26 cubic yards) of concrete per hour. Large capacity plants produce more than 90 cubic meters (118 cubic yards) of concrete per hour.

Benefits

- 9Flexibility: Modular plants can be designed and assembled to meet the specific needs of a project.

- 9Cost savings: Modular plants can be more cost-effective than traditional stationary or mobile plants, especially for short-term projects.

- 9Reduced environmental impact: Modular plants can reduce the environmental impact of construction, as they do not require transportation of plant components from a factory.

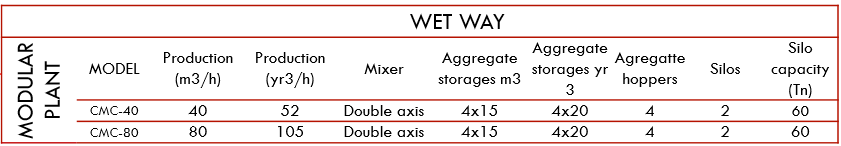

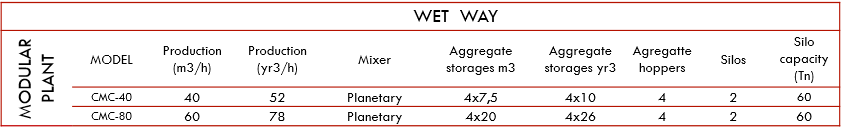

Our models

Would you need more information about our equipments ?